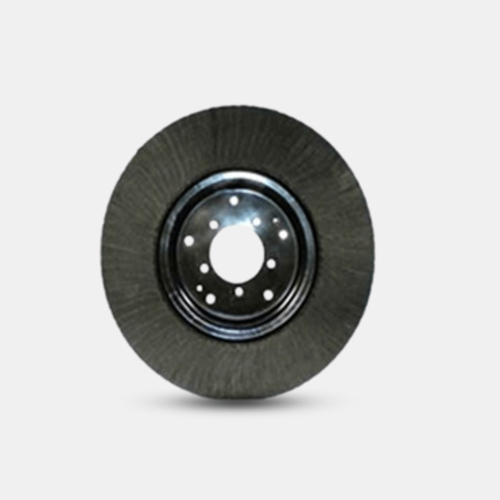

Laminated Tyres

Laminated Tyres Specification

- Tires & Tubes Type

- Solid Tire

- Usage

- Industrial

- Diameter

- 14.75/375mm Millimeter (mm)

- Width

- 3.75/95mm Millimeter (mm)

- Warranty

- Yes

Laminated Tyres Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Laminated Tyres

- NEW TREAD PATTERN

- WIDTH INCHES: 5.5"

- TIRE SIZE INCHES: 21" Diameter

- CAPACITY LBS: 2000

- HUB BOLT PATTERN: 4 on 5" centered

- HUB BOLT CENTERED: 3.50"

- CENTER HUB HOLE: 4" diameter

- TIRE DESIGN: Laminated

- WEIGHT LBS: 70

- PACKAGE QUANTITY: 1 pc.

- OEM, Flat Free, Laminated, 5.5" W x 21" T, 4 Bolts on 5" centered, center hub hole 4" diameter.

- Fits: Most major brands like Land Pride, Woods, John Deere, fits most batwing cutters with a 4 bolt mounting pattern.

- They are a solid rubber tire and they truly offer NO FLATS! Not for highway use

- Usually ships within 24 hrs of order placement excluding weekends and holidays

Durable Design for Industrial Demands

These laminated solid tyres are constructed to handle rigorous industrial tasks. Their robust lamination offers extra strength, while the solid format eliminates risks of punctures or blowouts, thus reducing downtime and maintenance costs for busy operations.

Versatile and Reliable Performance

Suitable for multiple industrial vehicles, these tyres deliver stable traction and consistent load-bearing capabilities. Their standard width and diameter ensure compatibility with a wide range of machinery used across manufacturing and logistics sectors in India.

FAQs of Laminated Tyres:

Q: How are laminated solid tyres installed on industrial equipment?

A: Laminated solid tyres are typically pressed onto the wheel rims using hydraulic presses to ensure a secure fit. Professional installation by experienced technicians is recommended to guarantee optimal performance and safety.Q: What benefits do laminated tyres offer compared to pneumatic tyres in industrial settings?

A: Laminated solid tyres provide excellent resistance to punctures and wear, making them ideal for harsh environments. They require less maintenance and offer consistent support, reducing operational interruptions and overall costs.Q: When should I consider replacing laminated solid tyres?

A: Replacement is necessary when you observe significant tread wear, surface cracks, or decreased traction. Regular inspections should be scheduled to ensure timely replacements and maintain equipment efficiency and safety.Q: Where are these laminated tyres commonly used?

A: These tyres are widely used in industries such as warehousing, logistics, manufacturing, and material handling. They are especially suitable for equipment like forklifts, trolleys, and loaders that operate on hard surfaces.Q: What is the manufacturing process for these laminated solid tyres?

A: The tyres are produced using high-grade rubber compounds, which are layered and laminated for strength. The assembly undergoes curing and quality checks before being sized to the specified dimensions: 3.75 (95mm) width and 14.75 (375mm) diameter.Q: How does the warranty for laminated tyres work?

A: The included warranty covers defects in materials or workmanship under normal industrial use. Should any issues arise within the warranty period, customers are advised to contact their supplier for assessment and suitable resolution.Q: What exporters, distributors, or suppliers in India provide these tyres?

A: A variety of companies across India manufacture, distribute, and export laminated solid tyres. It is best to source from reputable dealers or manufacturers who offer certified products and after-sales support.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Laminated Tyre Category

Laminated Tyre

Price 1050.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Tires & Tubes Type : Solid Tire

Width : 5.25/133mm Millimeter (mm)

Diameter : 20.75/527mm Millimeter (mm)

Usage : Industrial

Laminated Tyre 5x8x15

Price 1050.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Tires & Tubes Type : Solid Tire

Width : 4.75/ 121mm Millimeter (mm)

Diameter : 14.75/375mm Millimeter (mm)

Usage : Industrial

Laminated Tyre 6x9x21

Price 1050.0 INR / Piece

Minimum Order Quantity : 500 Pieces

Tires & Tubes Type : Solid Tire

Width : 5.25 / 133mm Millimeter (mm)

Diameter : 20.75 /527mm Millimeter (mm)

Usage : Industrial